Making the Most of Your CNC Machine’s Capabilities with 2D Files

Table of Contents

“Unlocking Full Potential: Maximizing CNC Machine Capabilities with 2D Files”

Introduction

Making the Most of Your CNC Machine’s Capabilities with 2D Files is a comprehensive guide that provides insights into maximizing the potential of CNC machines using 2D files. It explores the various techniques and strategies that can be employed to enhance the efficiency and precision of CNC machining processes. The guide also delves into the importance of 2D files in CNC machining, explaining how they can be used to simplify complex procedures, reduce errors, and increase overall productivity. It is an essential resource for anyone seeking to optimize their CNC machine operations using 2D files.

Maximizing CNC Machine Efficiency with 2D Files: A Comprehensive Guide

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry, offering unparalleled precision, efficiency, and versatility. These machines, which use computerized controls to operate and manipulate machine tools, can produce complex and intricate parts with minimal human intervention. However, to truly harness the full potential of your CNC machine, it is essential to understand how to effectively use 2D files. This article provides a comprehensive guide on maximizing CNC machine efficiency with 2D files.

2D files, also known as two-dimensional files, are digital files that represent objects in a two-dimensional space. They are commonly used in CNC machining to create flat, planar parts. These files can be created using various software programs, including AutoCAD, SolidWorks, and Adobe Illustrator. The key to maximizing your CNC machine’s capabilities with 2D files lies in understanding how to create, manipulate, and optimize these files for your specific machining needs.

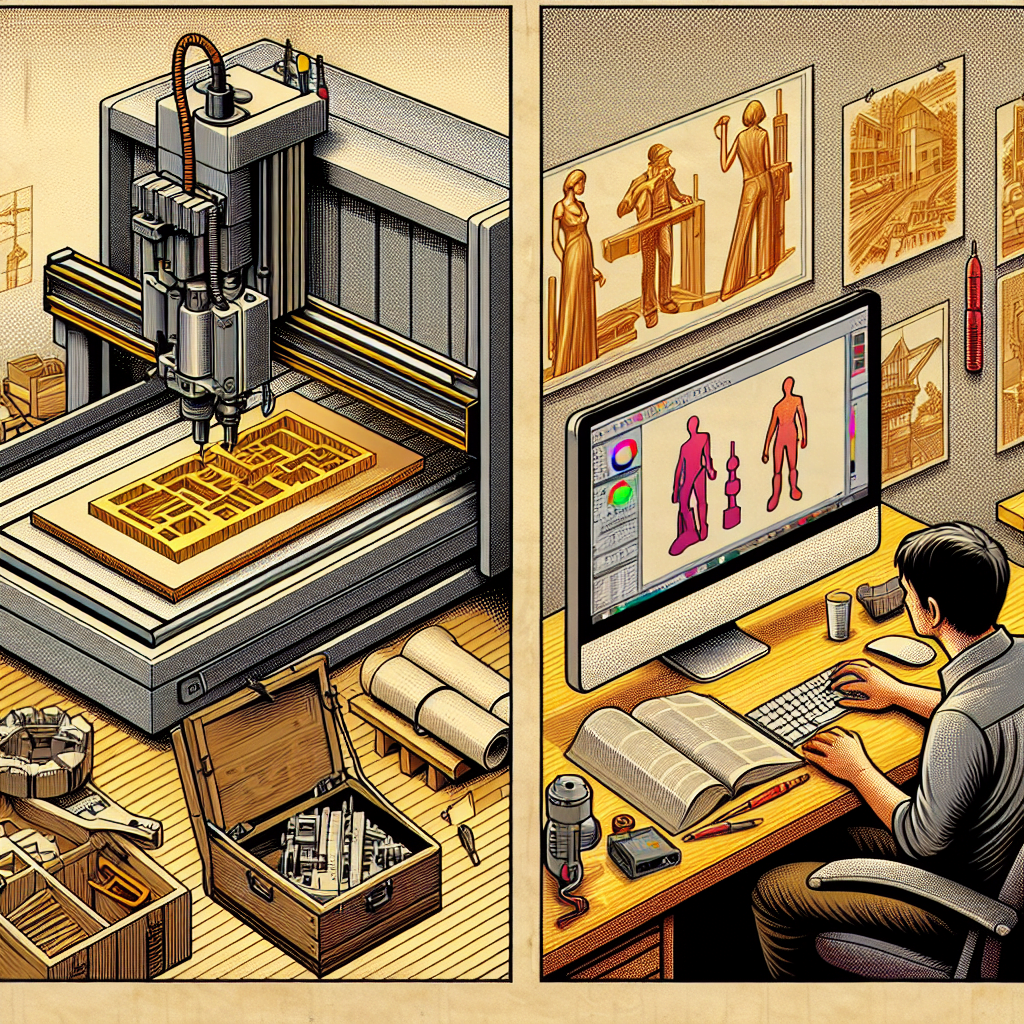

Creating 2D files for CNC machining involves designing the part in a CAD (Computer-Aided Design) program. This process requires a thorough understanding of the part’s specifications and the CNC machine’s capabilities. It is crucial to ensure that the design is feasible for CNC machining, taking into account factors such as the machine’s tooling capabilities, the material to be machined, and the desired level of precision.

Once the 2D file has been created, it can be manipulated to optimize the machining process. This may involve adjusting the design to reduce machining time, minimize material waste, or improve the part’s quality. For instance, by strategically placing the part’s features, you can minimize tool changes and movements, thereby reducing machining time. Similarly, by optimizing the part’s layout on the material, you can minimize material waste.

Another critical aspect of maximizing CNC machine efficiency with 2D files is choosing the right machining strategies. Different strategies can be used depending on the part’s complexity, the material, and the CNC machine’s capabilities. For instance, for simple, flat parts, a 2.5D machining strategy, which involves machining the part in layers, may be sufficient. However, for more complex parts, a 3D machining strategy, which involves machining the part from multiple angles, may be necessary.

Finally, it is essential to validate the 2D file before sending it to the CNC machine. This involves checking the file for errors and ensuring that it is optimized for the specific CNC machine. Various software tools can be used for this purpose, including CAM (Computer-Aided Manufacturing) programs, which can simulate the machining process and identify potential issues.

In conclusion, maximizing CNC machine efficiency with 2D files involves a combination of careful design, strategic manipulation, appropriate machining strategies, and thorough validation. By mastering these aspects, you can make the most of your CNC machine’s capabilities, producing high-quality parts efficiently and cost-effectively. Remember, the key to success lies in understanding your CNC machine’s capabilities and how to effectively leverage 2D files to meet your specific machining needs.

Unlocking the Full Potential of Your CNC Machine: The Power of 2D Files

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, offering unparalleled precision, efficiency, and versatility. These machines, which can be programmed to perform complex tasks with minimal human intervention, have become an indispensable tool for manufacturers worldwide. However, to truly unlock the full potential of your CNC machine, it is essential to understand the power of 2D files and how they can be used to maximize your machine’s capabilities.

2D files, or two-dimensional files, are digital representations of a physical object or design. They provide a flat, detailed view of the object from a single perspective, typically the top, side, or front. These files are commonly used in CNC machining because they allow for precise control over the machine’s movements, ensuring that each cut, drill, or mill is executed with pinpoint accuracy.

One of the primary benefits of using 2D files with your CNC machine is the ability to create intricate, detailed designs that would be difficult, if not impossible, to achieve manually. With 2D files, you can program your machine to cut complex shapes, create intricate patterns, or engrave detailed designs onto a variety of materials. This opens up a world of possibilities for manufacturers, allowing them to produce high-quality, custom products that stand out from the competition.

Another advantage of using 2D files is the increased efficiency they offer. By programming your CNC machine with a 2D file, you can automate the manufacturing process, reducing the need for manual labor and minimizing the risk of human error. This not only saves time and resources but also ensures consistent, high-quality results every time.

Furthermore, 2D files can be easily edited and adjusted, allowing for quick and easy modifications to the design. If a change needs to be made, you can simply update the file and reprogram the machine, rather than having to manually adjust the machine’s settings or start the manufacturing process from scratch. This flexibility makes 2D files an invaluable tool for manufacturers, particularly in industries where customization and adaptability are key.

However, to make the most of your CNC machine’s capabilities with 2D files, it’s important to have a solid understanding of how these files work and how to use them effectively. This includes knowing how to create and edit 2D files, how to program your machine with these files, and how to troubleshoot any issues that may arise. Fortunately, there are many resources available, including online tutorials, training courses, and user manuals, that can help you master these skills.

In conclusion, 2D files offer a powerful way to maximize the capabilities of your CNC machine. By harnessing the precision, efficiency, and versatility of these files, you can create intricate, high-quality products, streamline your manufacturing process, and stay ahead of the competition. So, if you’re looking to unlock the full potential of your CNC machine, it’s time to start exploring the possibilities of 2D files.

Leveraging 2D Files for Optimal CNC Machine Performance: A Step-by-Step Approach

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, offering unparalleled precision, efficiency, and versatility. These machines, which use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to automate the machining process, can produce complex, three-dimensional parts with a high degree of accuracy. However, to fully harness the capabilities of your CNC machine, it’s essential to understand how to effectively use 2D files.

2D files, or two-dimensional files, are a type of digital file that represents objects in a flat plane, using only length and width. These files are often used in CNC machining to create flat parts or to define the contours of a part. Despite their simplicity, 2D files can be a powerful tool in CNC machining when used correctly.

The first step in leveraging 2D files for optimal CNC machine performance is to understand the types of 2D files that your machine can accept. The most common types are DXF (Drawing Exchange Format) and DWG (DraWinG), both of which are supported by most CAD software. These file types are ideal for CNC machining because they can accurately represent the geometry of a part, including lines, curves, and angles.

Once you’ve identified the appropriate file type, the next step is to create or obtain a 2D file of the part you wish to machine. This can be done using CAD software, which allows you to design parts in a virtual environment. Alternatively, you can use a scanner or digital camera to capture an image of the part, then use image processing software to convert the image into a 2D file.

After obtaining the 2D file, you’ll need to import it into your CNC machine’s CAM software. This software will convert the 2D file into a set of instructions, or G-code, that the CNC machine can understand. The CAM software will also allow you to specify the toolpaths, or the paths that the cutting tool will follow during the machining process.

Once the G-code has been generated, it’s time to set up your CNC machine. This involves selecting the appropriate cutting tool, setting the correct spindle speed and feed rate, and positioning the workpiece on the machine’s table. It’s crucial to get these settings right, as they can significantly impact the quality of the finished part.

Finally, with everything set up, you can start the machining process. The CNC machine will follow the toolpaths specified in the G-code, cutting the workpiece to match the geometry defined in the 2D file. Throughout this process, it’s important to monitor the machine to ensure that it’s operating correctly and to make any necessary adjustments.

In conclusion, 2D files can be a valuable asset in CNC machining, allowing you to create precise, complex parts with ease. By understanding the types of 2D files that your CNC machine can accept, creating or obtaining a 2D file of the part you wish to machine, importing the file into your CAM software, setting up your machine correctly, and carefully monitoring the machining process, you can make the most of your CNC machine’s capabilities.

Conclusion

In conclusion, utilizing 2D files can significantly enhance the capabilities of your CNC machine. It allows for precise and accurate machining, simplifies the manufacturing process, and increases productivity. However, it requires a thorough understanding of the machine’s operations and the software used to create the 2D files.

Leave a Reply