How to Choose the Right Filament Material For Your 3D Prints

Sommario

“Unlock Your 3D Potential: Select the Perfect Filament for Flawless Prints!”

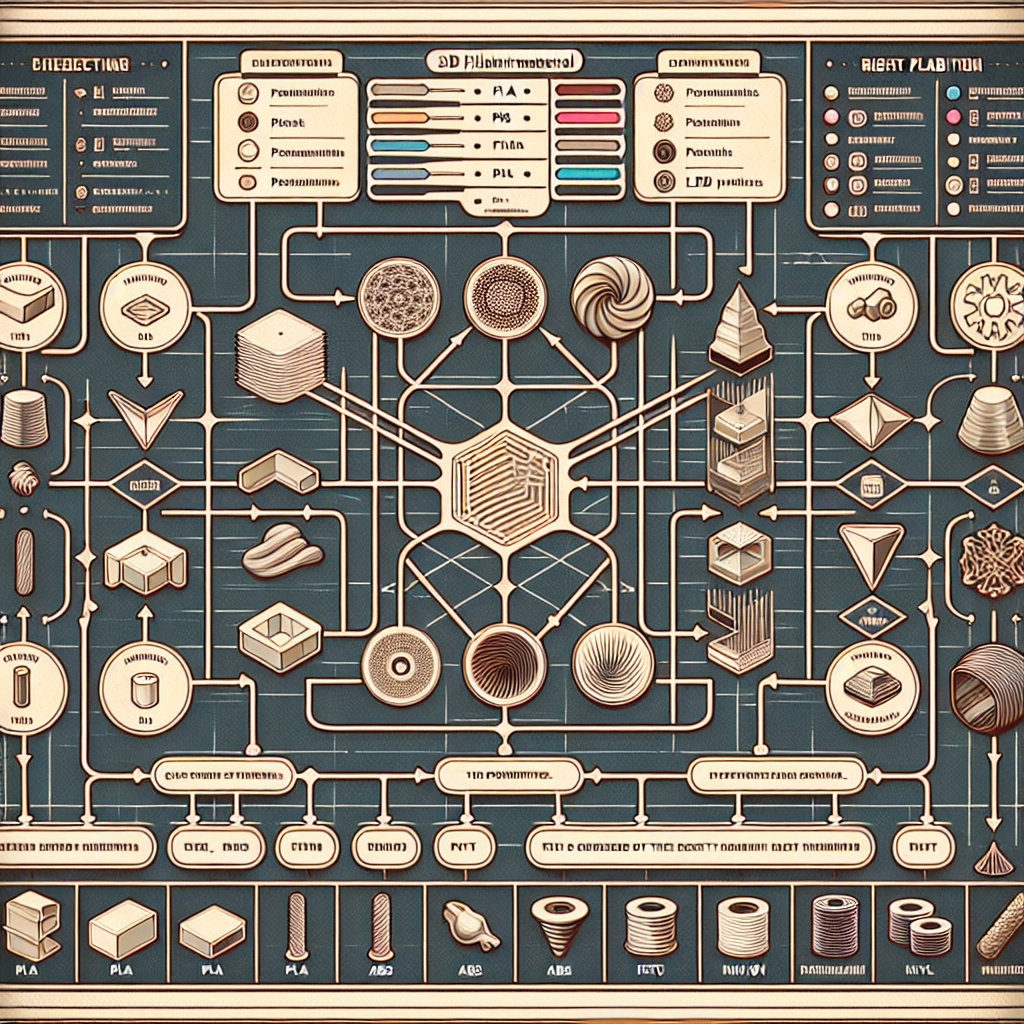

Choosing the right filament material for your 3D prints is crucial for achieving the desired quality, durability, and functionality of your printed objects. The selection process involves understanding the different properties of available materials, considering the intended application of the printed item, and ensuring compatibility with your 3D printer. Factors such as strength, flexibility, thermal resistance, and aesthetic qualities like color and finish must be taken into account. Additionally, environmental conditions, such as exposure to chemicals or UV light, can influence the decision. With a wide variety of filament materials on the market, including PLA, ABS, PETG, TPU, and specialty composites, it is important to thoroughly evaluate your needs and the characteristics of each option to make an informed choice that aligns with your project requirements.

Understanding the Properties of Different 3D Printing Filaments

How to Choose the Right Filament Material For Your 3D Prints

In the realm of 3D printing, selecting the appropriate filament material is crucial for achieving the desired outcome of your print. The filament is the raw material that a 3D printer uses to create objects, and its properties significantly influence the strength, flexibility, durability, and appearance of the final product. With a myriad of filament types available, understanding the characteristics of each is essential for making an informed decision that aligns with the specific requirements of your project.

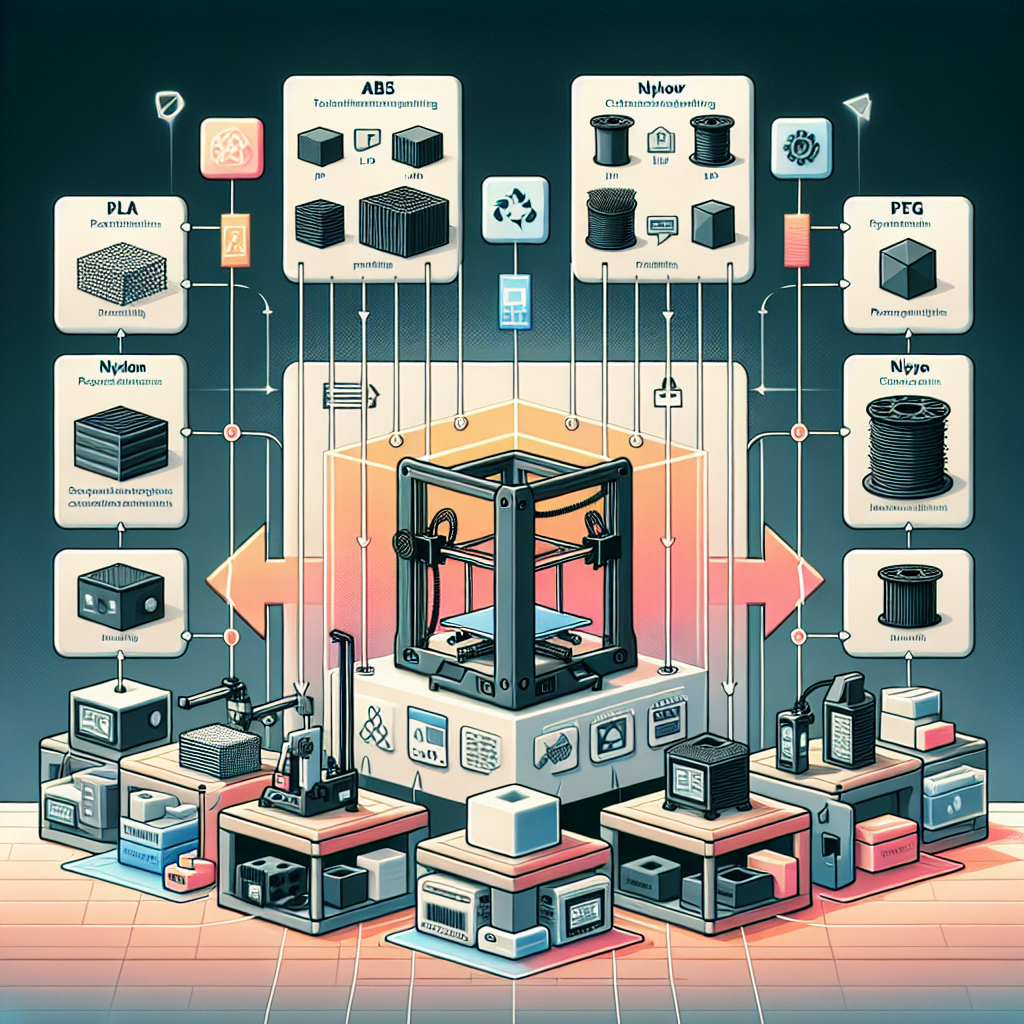

The most commonly used filament is Acrylonitrile Butadiene Styrene (ABS). Known for its strength and heat resistance, ABS is a popular choice for functional parts that must endure high temperatures and mechanical stress. However, it can be challenging to work with due to its tendency to warp during cooling, and it requires a heated print bed and an enclosed printing environment to manage these issues effectively.

Transitioning to another widely favored option, Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable resources like cornstarch or sugarcane. PLA is user-friendly, offering ease of printing with minimal warping and does not necessitate a heated bed. It’s ideal for beginners and for printing models or parts that do not need to withstand high temperatures or loads. However, its lower melting point is a limitation for applications where the printed object might be exposed to heat.

For those seeking a filament with enhanced durability and flexibility, Thermoplastic Polyurethane (TPU) is an excellent choice. TPU is a flexible, rubber-like material that can withstand compression and tension, making it perfect for printing items like phone cases, seals, or even wearable items. It does require a printer capable of handling flexible materials and may need slower print speeds to ensure the best quality.

When the project demands a material with high strength-to-weight ratio and the ability to withstand prolonged outdoor exposure, Polyethylene Terephthalate Glycol-modified (PETG) is a go-to filament. PETG combines the ease of printing found in PLA with the durability of ABS, and it has the added benefit of being resistant to moisture and chemicals. It’s a versatile material suitable for a wide range of applications, from mechanical parts to food-safe containers.

For specialized applications, there are filaments infused with other materials such as wood, metal, or carbon fiber. These composite filaments offer unique finishes and properties, such as the aesthetic of real wood or the enhanced stiffness and strength provided by carbon fiber. However, they often require specific printer settings and may be abrasive to standard nozzles, necessitating upgrades to hardened steel nozzles.

In addition to these properties, it’s important to consider the environmental impact of your chosen filament. While PLA is biodegradable under industrial composting conditions, other plastics like ABS contribute to plastic waste. Recycling or using filaments made from recycled materials can be a more sustainable choice.

Ultimately, the right filament for your 3D prints depends on a balance of factors including the intended use of the printed object, the printer’s capabilities, and your own experience level. By carefully considering the mechanical properties, ease of use, aesthetic qualities, and environmental impact of each filament type, you can select the material that best suits your project’s needs. With the right filament, you can optimize the performance and appearance of your 3D prints, ensuring successful outcomes for a wide array of creative and functional endeavors.

A Guide to Selecting Filament Materials Based on Print Object Functionality

How to Choose the Right Filament Material For Your 3D Prints

In the realm of 3D printing, the selection of filament material is as critical as the design of the object itself. The functionality of the printed object is inherently tied to the type of filament used, making the choice a pivotal decision in the printing process. Understanding the properties and applications of various filament materials is essential for achieving the desired outcome in your 3D prints.

The most commonly used filament in 3D printing is Polylactic Acid (PLA). Known for its ease of use, PLA is a biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane. It is the go-to material for beginners due to its low printing temperature, minimal warping, and the absence of harmful fumes. PLA is ideal for printing decorative items, prototypes, and products that do not require high strength or heat resistance. However, its biodegradability can be a drawback for objects intended for long-term use or exposure to the elements.

Transitioning to a more durable option, Acrylonitrile Butadiene Styrene (ABS) is a petroleum-based filament known for its toughness and impact resistance. ABS can withstand higher temperatures and is suitable for printing functional parts that must endure stress, such as gears, automotive components, and electronic housings. Despite its strength, ABS can be challenging to work with due to its tendency to warp and the need for a heated print bed. Additionally, it emits fumes that require proper ventilation during printing.

For applications demanding even higher performance, materials such as Polyethylene Terephthalate Glycol-modified (PETG) offer an excellent balance between ease of use and robustness. PETG combines the reliability of PLA with the durability of ABS, resulting in a filament that is strong, flexible, and resistant to both impact and temperature. It is also less prone to shrinkage and warping, making it suitable for a wide range of applications, including food containers and mechanical parts. Its clarity and gloss also make it an attractive option for aesthetically pleasing prints.

In scenarios where high-temperature resistance and strength are paramount, filaments such as Polycarbonate (PC) and Polyether Ether Ketone (PEEK) come into play. PC offers superior heat resistance and transparency but requires high printing temperatures, making it less accessible for standard desktop 3D printers. PEEK, on the other hand, is an engineering-grade material with exceptional mechanical and chemical resistance properties. It is used in the aerospace, automotive, and medical industries but is one of the most expensive filaments and requires specialized equipment to print.

For specialized applications, there are filaments with unique properties, such as conductive, magnetic, or glow-in-the-dark features. These materials allow for the creation of objects with specific functionalities that go beyond the structural characteristics of standard filaments.

When choosing the right filament material for your 3D prints, it is crucial to consider the intended use of the object. Factors such as strength, flexibility, temperature resistance, and exposure to chemicals or outdoor conditions should guide your selection. Additionally, printer compatibility and your own experience level with 3D printing must be taken into account to ensure a successful print.

In conclusion, the choice of filament material has a profound impact on the functionality and longevity of 3D printed objects. By carefully assessing the requirements of the intended application and balancing them with the capabilities of your 3D printer, you can select the most appropriate filament to bring your creations to life. Whether you opt for the user-friendly PLA, the durable ABS, the versatile PETG, or venture into high-performance materials like PC and PEEK, the right filament will ensure that your 3D prints meet both your expectations and their functional demands.

Comparing PLA, ABS, PETG, and More: Which Filament Fits Your 3D Printing Needs?

How to Choose the Right Filament Material For Your 3D Prints

In the realm of 3D printing, selecting the appropriate filament material is crucial for achieving the desired outcome of your print. The choice of filament can significantly influence the strength, flexibility, durability, and finish of the final product. Among the plethora of options available, PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol) are the most commonly used materials, each with its unique properties and applications.

PLA is often the go-to filament for beginners due to its ease of use and environmental friendliness. Derived from renewable resources such as cornstarch or sugarcane, PLA is biodegradable and emits a pleasant, sweet smell when heated. It prints at lower temperatures, which means it doesn’t require a heated bed, making it compatible with a wide range of 3D printers. PLA’s rigidity, however, can be a drawback for items that require flexibility, as it can become brittle over time or under stress. Moreover, its low melting point makes it unsuitable for objects that will be exposed to high temperatures.

Transitioning to ABS, this filament is known for its toughness and impact resistance. It is the same material used in Lego bricks, which speaks volumes about its durability. ABS can withstand higher temperatures and offers some degree of flexibility, which makes it suitable for functional parts that might be subject to stress or heat, such as automotive components or electronic housings. However, printing with ABS can be challenging due to its tendency to warp, and it requires a heated bed and ideally an enclosed print chamber to control cooling. Additionally, ABS emits fumes that can be unpleasant and should be printed in a well-ventilated area.

PETG stands as a middle ground between PLA and ABS, combining the ease of printing found in PLA with the strength and durability akin to ABS. It has a higher temperature resistance than PLA and does not emit harmful fumes, making it a safer option for indoor printing. PETG is also hydrophobic, meaning it resists moisture, and has a glossy finish that can be appealing for visual prototypes or finished products. However, PETG can be sticky during printing, which can lead to stringing or blobbing if not dialed in correctly.

Beyond these three popular choices, there are specialized filaments for more specific applications. For instance, TPU (Thermoplastic Polyurethane) is a flexible filament that can be used for items that require elasticity such as phone cases or wearable items. Nylon is known for its strength and flexibility but requires high printing temperatures and is hygroscopic, meaning it absorbs moisture from the air, which can affect print quality if not stored properly.

When choosing the right filament for your 3D prints, it is essential to consider the intended use of the object. If you are creating decorative items or prototypes that do not need to endure stress, PLA might be the most suitable choice. For functional parts that require durability and heat resistance, ABS could be the better option. PETG offers a balance of usability and resilience, making it a versatile choice for a variety of prints.

Ultimately, the decision on which filament to use will depend on the specific requirements of the print job, the capabilities of your 3D printer, and your own experience and comfort level with different materials. Experimenting with different filaments and settings can help you discover the perfect match for your 3D printing needs, leading to successful and satisfying results.

Conclusione

Conclusione:

Choosing the right filament material for your 3D prints depends on the specific requirements of the project, including the desired strength, flexibility, durability, and aesthetic qualities of the final print. Factors such as the printing environment, printer capabilities, and post-processing needs should also be considered. Common filament materials include PLA for ease of use and biodegradability, ABS for strength and heat resistance, PETG for a balance of PLA and ABS properties, TPU for flexibility, and specialty filaments for unique applications. Ultimately, the right filament will align with the functional requirements of the printed object, the user’s experience level, and the capabilities of the 3D printer being used.

Lascia un commento