Progettare con uno scopo: creare progetti CNC 2D significativi

Sommario

“Designing with Purpose: Transforming Visions into Tangible 2D CNC Masterpieces.”

introduzione

Designing with Purpose – Creating Meaningful 2D CNC Projects is a comprehensive guide that explores the process of creating two-dimensional projects using Computer Numerical Control (CNC) technology. It emphasizes the importance of purposeful design, focusing on how to create projects that are not only aesthetically pleasing but also meaningful and functional. The guide covers various aspects of CNC design, including planning, material selection, tool path generation, and post-processing. It aims to equip readers with the knowledge and skills needed to effectively use CNC technology in their design projects, ultimately enhancing the value and impact of their creations.

Exploring the Art of Designing with Purpose for 2D CNC Projects

Designing with purpose is a concept that transcends the boundaries of traditional art and design. It is a philosophy that encourages creators to imbue their work with meaning and intention, thereby elevating their creations from mere objects to powerful tools of communication. This concept is particularly relevant in the realm of 2D CNC (Computer Numerical Control) projects, where the fusion of technology and creativity opens up a world of possibilities for meaningful design.

The art of designing with purpose for 2D CNC projects begins with a clear understanding of the project’s objectives. The designer must ask themselves: What is the purpose of this project? What message or emotion do I want to convey? The answers to these questions form the foundation upon which the design is built. Every line, curve, and detail in the design should serve to further these objectives, creating a cohesive whole that communicates the intended message effectively.

Once the objectives are clear, the designer can begin to explore different design elements and how they can be used to achieve these goals. For instance, the use of lines in a design can create a sense of direction or movement, guiding the viewer’s eye towards a particular point of interest. Similarly, the use of shapes can evoke certain emotions or associations. A circle, for instance, might symbolize unity or completeness, while a square might represent stability or order. By carefully considering the implications of these elements, the designer can create a design that resonates with the viewer on a deeper level.

However, designing with purpose for 2D CNC projects is not just about the visual aspects of the design. It also involves considering the practical aspects of the project. For instance, the designer must take into account the capabilities and limitations of the CNC machine that will be used to create the project. This includes factors such as the size of the machine, the materials it can work with, and the level of detail it can achieve. By understanding these constraints, the designer can create a design that is not only visually appealing but also feasible to produce.

Moreover, the designer must also consider the end use of the project. Will it be a decorative piece, a functional item, or perhaps a combination of both? This will influence the design choices, as the project must not only look good but also serve its intended purpose effectively. For instance, a decorative piece might prioritize aesthetics over durability, while a functional item might require a more robust design.

In conclusion, designing with purpose for 2D CNC projects is a multifaceted process that involves a careful balance of creativity, practicality, and intentionality. It requires the designer to think deeply about the purpose of the project, the message they want to convey, and the best way to achieve these goals within the constraints of the CNC machine and the end use of the project. By doing so, they can create a design that is not only visually appealing but also meaningful and impactful. This, in essence, is the art of designing with purpose.

Creating Meaningful 2D CNC Projects: A Comprehensive Guide

Designing with purpose is a fundamental principle in creating meaningful 2D CNC projects. It involves a thoughtful process that goes beyond the mere aesthetics of a design, focusing on the functionality, relevance, and impact of the project. This comprehensive guide aims to provide insights into how to create meaningful 2D CNC projects, emphasizing the importance of purposeful design.

The first step in designing with purpose is understanding the project’s objective. This involves identifying the needs and expectations of the end-user, as well as the context in which the project will be used. For instance, if the project is a piece of furniture, it should not only be visually appealing but also comfortable and durable. Similarly, if the project is a signboard, it should be easily readable and withstand outdoor conditions. Understanding the project’s objective helps in making informed design decisions and ensures that the final product serves its intended purpose effectively.

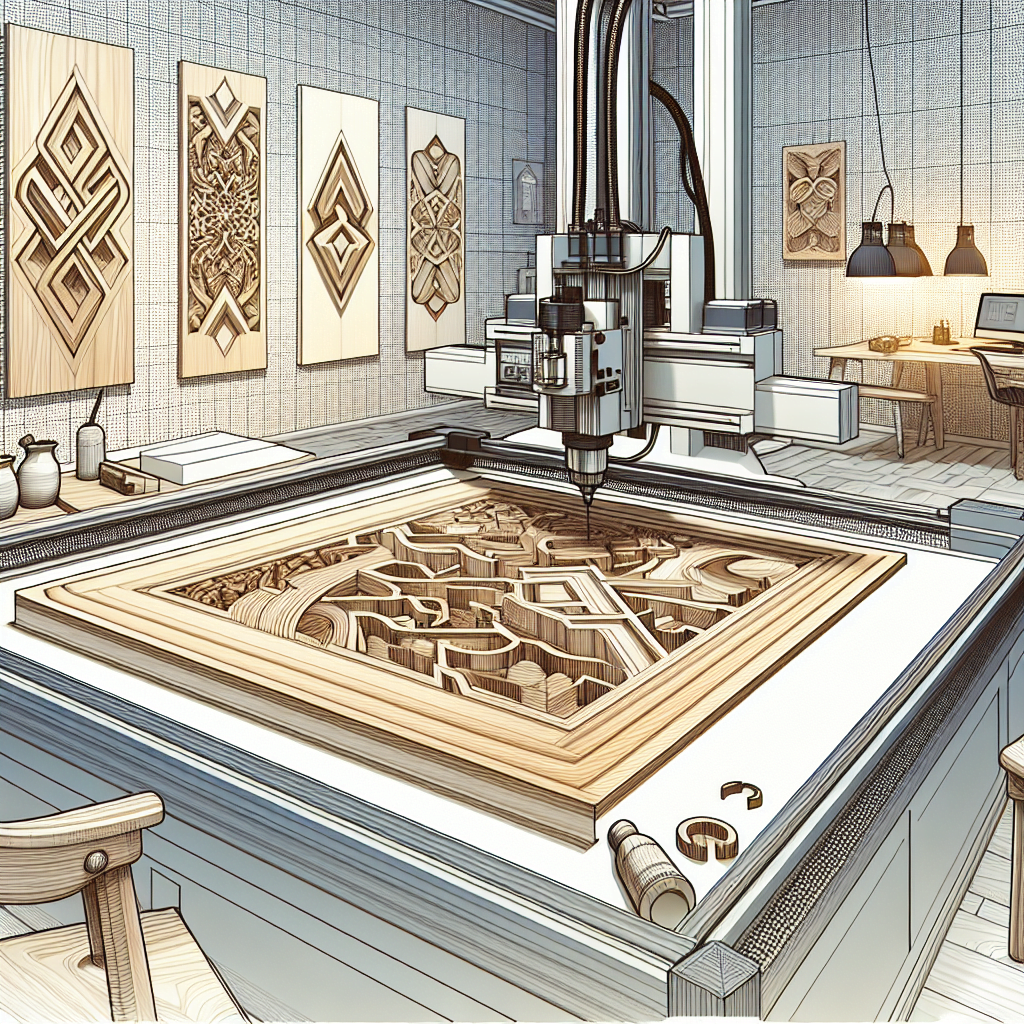

Once the project’s objective is clear, the next step is conceptualizing the design. This involves brainstorming ideas, sketching rough drafts, and refining them until a final design is achieved. During this stage, it’s crucial to consider the technical capabilities of the CNC machine. For instance, intricate designs may not be feasible on a basic CNC machine, while simple designs may not fully utilize the capabilities of a high-end CNC machine. Therefore, the design should strike a balance between creativity and feasibility, ensuring that it can be accurately and efficiently produced on the CNC machine.

After finalizing the design, the next step is creating a digital model using a CAD (Computer-Aided Design) software. This involves translating the design into a digital format that the CNC machine can understand. During this stage, it’s important to pay attention to details such as dimensions, tolerances, and tool paths. These factors significantly influence the quality of the final product. For instance, incorrect dimensions can result in a product that doesn’t fit its intended space, while incorrect tool paths can lead to inefficient machining and poor surface finish.

Once the digital model is ready, the next step is setting up the CNC machine. This involves selecting the appropriate tools, materials, and cutting parameters. For instance, hard materials require sturdy tools and slow cutting speeds, while soft materials can be machined with less robust tools and faster cutting speeds. Proper machine setup ensures that the project is produced accurately and efficiently, minimizing waste and maximizing productivity.

The final step in designing with purpose is evaluating the finished product. This involves assessing the product against the project’s objective and making necessary adjustments. For instance, if the product doesn’t meet the end-user’s needs or expectations, the design may need to be revised. Similarly, if the product doesn’t withstand its intended conditions, the material or machining process may need to be changed. Continuous evaluation and improvement ensure that the product remains relevant and effective, fulfilling its intended purpose.

In conclusion, designing with purpose is a holistic approach to creating meaningful 2D CNC projects. It involves understanding the project’s objective, conceptualizing the design, creating a digital model, setting up the CNC machine, and evaluating the finished product. By following these steps, designers can create 2D CNC projects that are not only aesthetically pleasing but also functional, relevant, and impactful.

The Impact of Purposeful Design in 2D CNC Projects

Designing with purpose is a fundamental aspect of creating meaningful 2D CNC (Computer Numerical Control) projects. The impact of purposeful design in these projects is profound, as it not only enhances the aesthetic appeal of the final product but also improves its functionality and usability. This article delves into the significance of purposeful design in 2D CNC projects and how it can be effectively implemented to create meaningful and impactful designs.

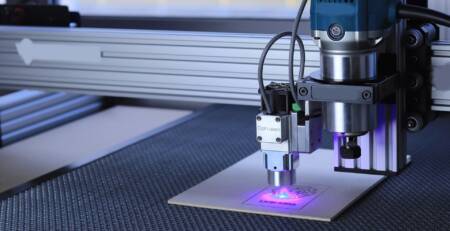

The essence of purposeful design lies in its ability to solve problems and meet specific needs. In the context of 2D CNC projects, this means creating designs that are not only visually appealing but also serve a specific purpose. For instance, a CNC-cut wooden sign may be designed to enhance the décor of a room, while a CNC-machined metal part may be designed to fit into a larger mechanical assembly. In both cases, the design serves a specific purpose, which adds value to the final product.

The impact of purposeful design in 2D CNC projects can be seen in various ways. Firstly, it enhances the functionality of the final product. A well-designed CNC project will perform its intended function efficiently and effectively. This is particularly important in industrial applications, where the performance of a CNC-machined part can directly impact the overall efficiency of a manufacturing process.

Secondly, purposeful design improves the usability of the final product. A CNC project that is designed with the end-user in mind will be easy to use and intuitive. This not only enhances the user experience but also increases the likelihood of the product being used as intended. For instance, a CNC-cut sign that is designed to be easily read from a distance will be more effective in conveying its message than one that is not.

Thirdly, purposeful design enhances the aesthetic appeal of the final product. A CNC project that is designed with attention to detail and a keen eye for aesthetics will be visually pleasing. This can significantly enhance the perceived value of the product, making it more appealing to potential customers or users.

Implementing purposeful design in 2D CNC projects requires a thorough understanding of the project’s objectives and the needs of the end-user. It involves careful planning and thoughtful consideration of various design elements, such as shape, size, material, and finish. It also requires a deep understanding of CNC machining processes and their capabilities, as this can greatly influence the design of the project.

In conclusion, the impact of purposeful design in 2D CNC projects is significant. It enhances the functionality, usability, and aesthetic appeal of the final product, making it more valuable and meaningful. By understanding the objectives of the project and the needs of the end-user, designers can create CNC projects that are not only visually appealing but also serve a specific purpose. This approach to design not only elevates the quality of the final product but also contributes to the overall success of the project.

Conclusione

In conclusion, designing with purpose in creating meaningful 2D CNC projects involves a thoughtful process that combines creativity, technical skills, and a clear understanding of the project’s objective. It requires careful planning, precision, and attention to detail to ensure the final product is not only aesthetically pleasing but also functional and meaningful. The use of CNC technology allows for high levels of accuracy and consistency, making it an invaluable tool in the design process. Ultimately, the success of a 2D CNC project lies in its ability to effectively communicate or serve its intended purpose.

Lascia un commento