Maintaining a CNC Router – Preventative Care Tips

Tabla de contenido

“Maximize Precision, Minimize Downtime: Mastering CNC Router Maintenance”

Introducción

Maintaining a CNC router is crucial for ensuring consistent performance, accuracy, and longevity of the machine. Preventative care involves regular inspections, cleaning, lubrication, and adjustments to prevent wear and tear, as well as to identify potential issues before they lead to significant downtime or costly repairs. Proper maintenance not only extends the life of the CNC router but also helps to maintain the quality of the work it produces. By adhering to a comprehensive maintenance schedule, operators can minimize the risk of unexpected breakdowns and ensure that the machine operates at peak efficiency.

Essential Preventative Maintenance for Your CNC Router

Maintaining a CNC Router – Preventative Care Tips

In the realm of precision machining, CNC routers stand as pivotal equipment, enabling artisans and manufacturers to carve, engrave, and cut with exceptional accuracy. However, the sophistication of these machines necessitates a rigorous maintenance regimen to ensure their longevity and reliability. Essential preventative maintenance for your CNC router not only safeguards your investment but also upholds the quality of your work.

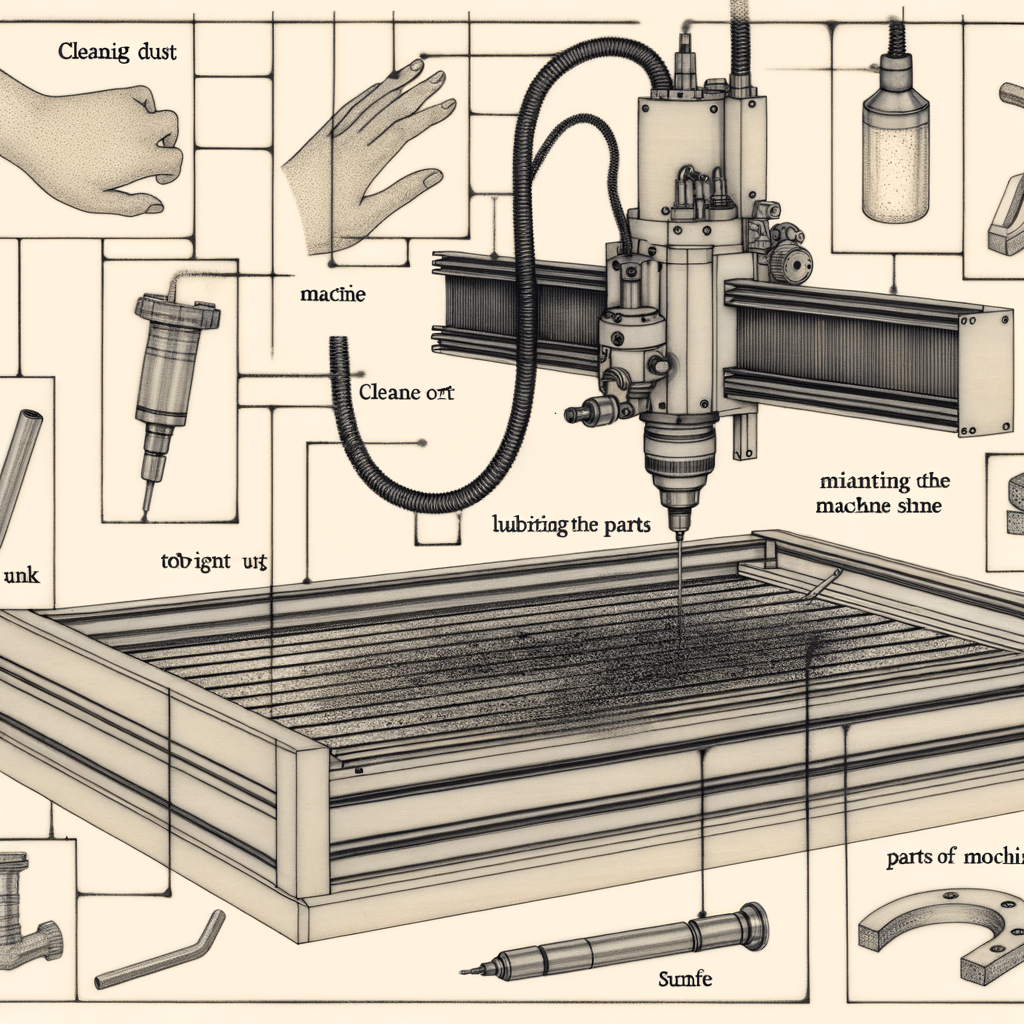

The cornerstone of preventative care for CNC routers is regular cleaning. Dust and debris are the nemeses of precision equipment, potentially leading to wear and tear on moving parts. After each use, it is imperative to remove these particles using a vacuum or compressed air, paying close attention to the spindle, collets, and lead screws. This routine not only preserves the machine’s integrity but also maintains the accuracy of your cuts.

Lubrication is another critical aspect of CNC router maintenance. The moving parts of the machine, such as the linear guides and ball screws, require periodic lubrication to operate smoothly. Utilizing the correct type of lubricant is essential; it should be compatible with the materials used in your CNC router. Manufacturers often provide guidelines on the appropriate lubricants and the frequency of application. Adhering to these recommendations can prevent premature wear and costly repairs.

In addition to cleaning and lubrication, it is vital to regularly check the alignment of your CNC router. Misalignment can lead to imprecise cuts and even damage to the workpiece or the machine itself. By routinely inspecting and calibrating the alignment, you can ensure that your router continues to operate at peak performance. This process may involve adjusting the gantry, checking the squareness of the axes, and verifying that the spindle is perpendicular to the worktable.

Another preventative measure is to monitor the condition of the cutting tools. Dull or damaged tools not only compromise the quality of your work but can also place undue stress on the machine. Regularly inspecting and replacing or sharpening tools as needed can prevent these issues. It is also beneficial to keep a log of tool usage to predict when maintenance or replacement will be necessary.

Software updates and backups are often overlooked in the context of CNC router maintenance, yet they are equally important. Manufacturers frequently release updates that can enhance the performance of your machine or address known issues. Keeping your software up-to-date ensures that you are taking advantage of the latest improvements. Additionally, maintaining backups of your CNC programs and parameters protects against data loss in the event of a system failure.

Lastly, training and adherence to operational protocols cannot be understated. Operators should be well-versed in the proper use and handling of the CNC router. Mishandling or operating the machine outside of its intended parameters can lead to breakdowns and reduce its lifespan. A well-trained operator is a key component in the preventative maintenance chain, capable of recognizing early signs of potential problems and taking appropriate action.

In conclusion, a comprehensive preventative maintenance program is essential for the optimal functioning of your CNC router. By incorporating regular cleaning, lubrication, alignment checks, tool maintenance, software updates, and operator training into your routine, you can prevent many common issues that could otherwise lead to downtime or expensive repairs. Such diligence not only extends the life of your CNC router but also ensures that it continues to produce work of the highest quality.

Maximizing CNC Router Lifespan with Regular Maintenance Schedules

Maintaining a CNC Router – Preventative Care Tips

In the realm of precision manufacturing, CNC routers stand as pivotal equipment, enabling artisans and manufacturers to carve, engrave, and cut with exceptional accuracy. However, the sophistication of these machines necessitates a rigorous maintenance regimen to ensure their longevity and reliability. By adhering to regular maintenance schedules, operators can maximize the lifespan of their CNC routers, thereby safeguarding their investment and maintaining productivity.

The cornerstone of preventative care for CNC routers is a well-structured maintenance schedule. This schedule should be meticulously crafted, taking into account the manufacturer’s recommendations, the intensity of machine usage, and the specific materials being processed. Regular maintenance not only prevents unexpected breakdowns but also ensures that the machine operates at peak efficiency, which is crucial for maintaining the precision of the work produced.

One of the primary steps in maintaining a CNC router is the regular inspection and cleaning of its components. Dust and debris, if left unchecked, can accumulate on the machine, leading to potential damage and wear. It is imperative to keep the router clean, paying particular attention to the spindle, collets, and tool holders. A clean machine is less likely to suffer from the friction and heat that can cause premature wear.

Lubrication is another critical aspect of CNC router maintenance. Moving parts such as bearings, rails, and lead screws require regular lubrication to operate smoothly. The type of lubricant and the frequency of application should align with the manufacturer’s specifications. Proper lubrication reduces the risk of corrosion and wear, thereby extending the life of the machine’s moving parts.

In addition to cleaning and lubrication, it is essential to regularly check the alignment and calibration of the CNC router. Over time, the machine’s components can shift slightly, which can affect the accuracy of the cuts. By routinely calibrating the machine and ensuring that all parts are correctly aligned, operators can maintain the high precision that CNC routing requires.

Another preventative measure is to monitor the condition of the cutting tools. Dull or damaged tools not only compromise the quality of the finished product but also place additional stress on the machine, which can lead to premature failure. Regularly inspecting and replacing tools as needed is a cost-effective way to maintain the overall health of the CNC router.

Software updates and backups are often overlooked in the maintenance of CNC routers, yet they are just as important as the physical upkeep of the machine. Keeping the software up to date ensures that the router is equipped with the latest features and bug fixes, which can improve performance and prevent operational issues. Additionally, maintaining backups of critical software and operational parameters can prevent significant downtime in the event of a system failure.

Finally, training operators on proper machine usage and maintenance is vital. A well-trained operator is more likely to recognize the early signs of potential issues and can take proactive steps to address them before they escalate into major problems. Investing in training not only enhances the efficiency of the machine but also contributes to a safer working environment.

In conclusion, a CNC router is a significant investment that demands a proactive approach to maintenance. By establishing and adhering to a regular maintenance schedule, operators can ensure that their CNC routers continue to operate at optimal levels, producing high-quality work while minimizing the risk of downtime. Through diligent cleaning, lubrication, calibration, tool maintenance, software management, and operator training, the lifespan of a CNC router can be significantly extended, providing a reliable foundation for any precision manufacturing operation.

The Top Preventative Care Strategies for CNC Router Owners

Maintaining a CNC Router – Preventative Care Tips

In the realm of precision machining, CNC routers stand as pivotal equipment, enabling artisans and manufacturers to carve, engrave, and cut with exceptional accuracy. However, the sophistication of these machines necessitates a rigorous maintenance regimen to ensure their longevity and reliability. By adopting top preventative care strategies, CNC router owners can safeguard their investment and maintain peak performance.

The cornerstone of preventative maintenance is regular inspection. Diligent examination of the machine’s components can preemptively identify wear and tear, allowing for timely interventions before minor issues escalate into costly repairs. It is imperative to scrutinize the router’s spindle, collets, and bearings, as these are prone to stress and can significantly impact the machine’s precision if compromised. Additionally, checking the alignment of the gantry and ensuring that the rails and lead screws are straight will prevent inaccuracies in the machining process.

Lubrication plays a vital role in the smooth operation of a CNC router. Moving parts, such as bearings and rails, require consistent lubrication to minimize friction and wear. Utilizing the correct type of lubricant is equally important; manufacturers often provide specifications for the recommended lubricants that are compatible with their machines. Adhering to these guidelines not only extends the life of the components but also maintains the machine’s efficiency.

Dust and debris are the nemeses of CNC routers. The very nature of cutting and carving materials generates particulate matter that can infiltrate the machine’s sensitive areas. Therefore, implementing an effective dust extraction system is not just a matter of cleanliness but also a protective measure. Regularly cleaning the work area and the machine itself, including the removal of dust from the spindle fan, helps prevent overheating and potential damage to the electrical components.

Software updates and backups are often overlooked in the context of machine maintenance, yet they are crucial for the seamless operation of a CNC router. Manufacturers frequently release updates that enhance functionality, patch vulnerabilities, and improve compatibility with design software. Keeping the CNC router’s software up-to-date ensures that the machine operates with the latest improvements and security measures. Moreover, maintaining regular backups of the machine’s settings and programs guards against data loss in the event of a system failure.

Calibration is another essential aspect of preventative care. Over time, a CNC router may lose its calibration due to vibrations and regular use, leading to errors in the finished product. Periodic calibration ensures that the machine produces work of consistent quality and precision. This process may involve adjusting the steps per unit settings or realigning the machine’s axes to their original specifications.

Finally, training and education should not be underestimated. Operators who are well-versed in the machine’s functions and maintenance requirements are less likely to make errors that could lead to damage. Investing in ongoing training for staff can prevent mishandling and promote a culture of meticulous care for the equipment.

In conclusion, the top preventative care strategies for CNC router owners revolve around regular inspections, proper lubrication, diligent cleaning, software vigilance, precise calibration, and operator training. By embracing these practices, owners can ensure that their CNC routers continue to operate at their best, producing high-quality work while avoiding unnecessary downtime and repair costs. The adage “an ounce of prevention is worth a pound of cure” holds particularly true in the world of CNC machining, where the cost of prevention is far outweighed by the benefits of sustained machine performance and longevity.

Conclusión

Conclusión:

Maintaining a CNC router is crucial for ensuring its longevity, precision, and safety. Preventative care tips include regular cleaning to remove dust and debris, lubricating moving parts to reduce wear, checking and tightening components to prevent vibrations and inaccuracies, updating software to the latest versions for optimal performance, and scheduling routine inspections to catch potential issues early. By adhering to a consistent maintenance schedule, operators can minimize downtime, extend the life of the machine, and maintain the quality of their work.

Deja una respuesta