Key Accessories Every CNC Laser Cutter Owner Should Have

Tabla de contenido

“Enhance Precision and Safety: Essential Accessories for Every CNC Laser Cutter Enthusiast”

Introducción

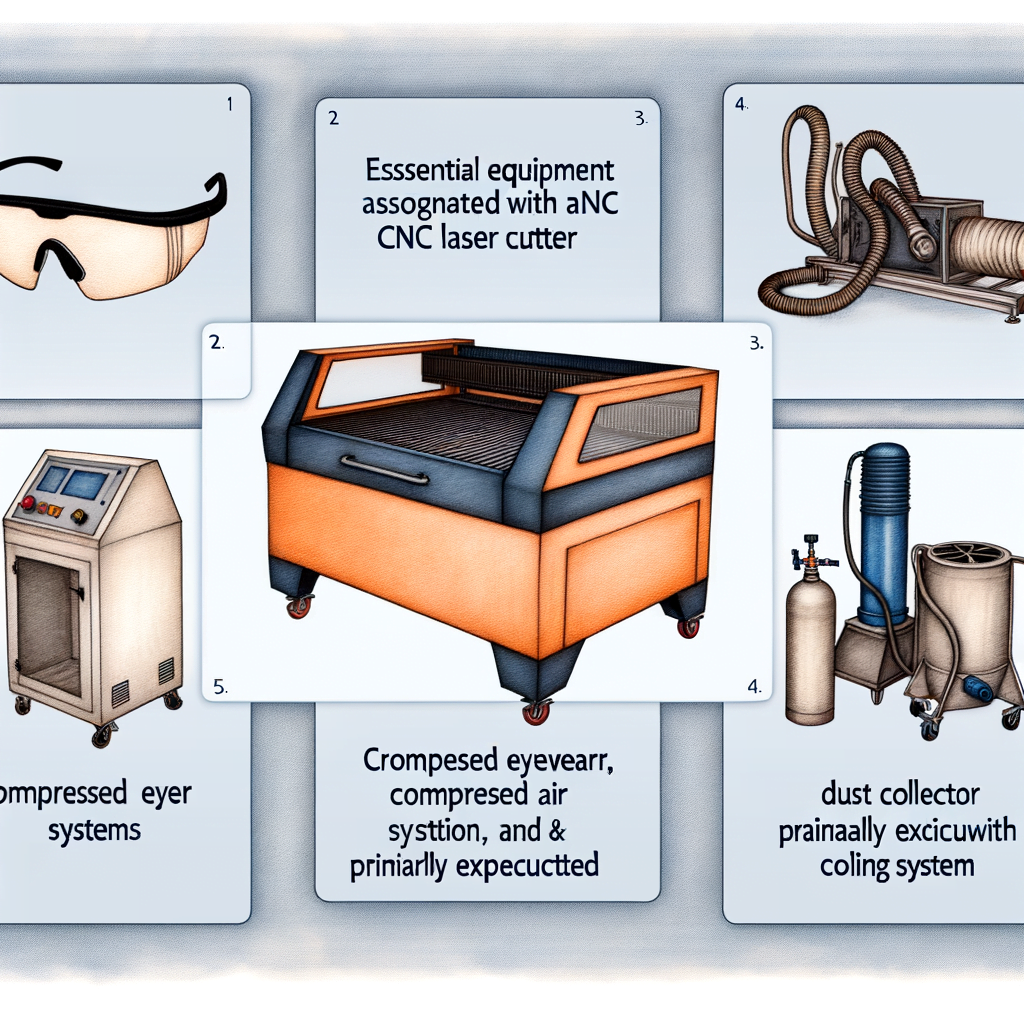

Key accessories are essential for CNC laser cutter owners to ensure efficient operation, maintenance, and safety. These accessories can range from protective gear to enhance safety, to supplementary tools that improve the precision and quality of cuts. Proper accessories can also extend the lifespan of the machine and help operators to utilize the laser cutter to its full potential. Essential accessories include laser safety glasses, air assist pumps, fume extraction systems, cooling systems, and maintenance tools. By investing in these key accessories, CNC laser cutter owners can maintain a productive workflow, achieve consistent results, and provide a safe working environment.

Essential Maintenance Tools for CNC Laser Cutter Upkeep

Title: Key Accessories Every CNC Laser Cutter Owner Should Have

For those who own a CNC laser cutter, ensuring the longevity and optimal performance of the machine is paramount. To achieve this, there are several essential maintenance tools that should be part of every owner’s toolkit. These accessories not only help in maintaining the machine but also in enhancing its functionality and safety.

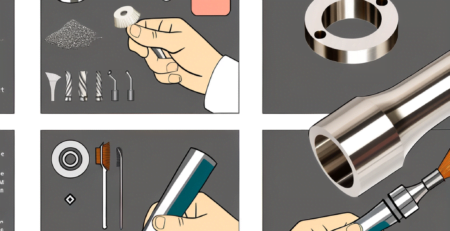

Firstly, one of the most critical accessories for maintaining a CNC laser cutter is a set of high-quality optics cleaning solutions and tools. The lenses and mirrors within the laser system are delicate and can accumulate dust and residues that can affect the laser’s focus and cutting precision. Specialized optics cleaning kits, which typically include lint-free wipes, cotton swabs, and cleaning solutions designed for optical components, are indispensable. Regular cleaning with these tools can prevent the buildup of contaminants that could otherwise lead to costly damage or downtime.

Another essential tool is a set of precision alignment tools. These are used to ensure that the laser beam is correctly aligned with the machine’s axes. Misalignment can lead to inaccurate cuts and reduced efficiency. Using these tools periodically to check and adjust the alignment can greatly improve the machine’s cutting accuracy and extend the life of the laser tube.

Furthermore, a reliable set of cooling system maintenance tools is crucial for any CNC laser cutter. The cooling system, often a water chiller or air compressor, plays a vital role in preventing the laser from overheating. Overheating can cause significant damage to the laser tube and power supply. Tools such as coolant refractometers, pH meters, and anti-algae treatments help maintain the quality of the cooling medium, ensuring it effectively dissipates heat from the laser system.

In addition to these specialized tools, a comprehensive set of mechanical tools is necessary for general upkeep. This includes wrenches, screwdrivers, and pliers that fit the various nuts, bolts, and components of the machine. Having these tools on hand allows for quick adjustments and repairs, minimizing the downtime that can occur when waiting for a technician.

Moreover, a digital caliper is an invaluable tool for any CNC laser cutter owner. Precision is key in laser cutting, and a caliper can measure the thickness of materials to ensure the correct focus distance and cutting parameters are set. This not only helps in achieving high-quality cuts but also in reducing material waste.

Lastly, safety should never be overlooked when operating a CNC laser cutter. Proper safety gear, including laser-safe goggles and protective clothing, is essential to protect the operator from potential hazards such as laser reflections and fumes. Additionally, having a fire extinguisher designed for electrical fires and a first-aid kit nearby is prudent for handling any emergencies that may arise.

In conclusion, owning a CNC laser cutter comes with the responsibility of maintaining it to the highest standards. By equipping oneself with these key accessories, owners can perform essential maintenance tasks that not only preserve the machine’s life but also ensure its safe and efficient operation. Regular upkeep with the right tools can prevent unexpected breakdowns, maintain cutting precision, and ultimately save time and money. As such, investing in these essential maintenance tools is as important as the machine itself for anyone serious about their CNC laser cutting endeavors.

Top Safety Gear for CNC Laser Cutter Operators

Title: Key Accessories Every CNC Laser Cutter Owner Should Have

In the realm of precision manufacturing, CNC laser cutters stand out for their ability to produce intricate designs with remarkable accuracy. However, the very power that makes these machines so effective also necessitates a strong commitment to safety. Operators must be equipped with the right accessories to ensure a secure working environment. This article will explore the essential safety gear that every CNC laser cutter owner should have on hand.

First and foremost, protective eyewear is non-negotiable. CNC laser cutters emit intense beams of light that can cause severe eye damage, including permanent blindness, if proper precautions are not taken. Safety glasses or goggles designed specifically for laser use are crucial. These should have an optical density (OD) rating suitable for the type of laser in use, effectively blocking or attenuating the laser light to safe levels. Moreover, they should comply with the ANSI Z136.1 standard for laser safety, ensuring they meet rigorous protection criteria.

Beyond safeguarding one’s vision, respiratory protection is another key consideration. The laser cutting process can generate harmful fumes and particulate matter, especially when working with plastics, coated metals, or any materials that might release toxic substances when vaporized. A high-quality respirator or mask with appropriate filters can protect the operator from inhaling these dangerous byproducts. It is important to select a respirator that fits well and provides a proper seal to prevent unfiltered air from being inhaled.

Hearing protection is another accessory that may be overlooked but is equally important. While laser cutters are not as loud as some other industrial machinery, the noise levels can still be significant, especially in enclosed spaces or during extended periods of operation. Earplugs or earmuffs that provide adequate noise reduction can help prevent hearing loss and reduce fatigue from constant noise exposure.

In addition to personal protective equipment, fire safety accessories are indispensable. Given that laser cutters work by burning or melting materials, there is always a risk of fire. Having a fire extinguisher rated for electrical fires and appropriate for the materials being cut is a must-have in any laser cutting workspace. It’s also wise to have a fire blanket on hand for smothering any flames that might arise from the cutting process.

Another critical accessory is a proper ventilation system. Effective exhaust ventilation not only helps to clear out fumes and airborne particles but also aids in maintaining a stable temperature and reducing the risk of fire. A well-designed ventilation system will capture contaminants at the source and expel them safely outside the workspace, ensuring a clean and safe environment for the operator.

Finally, skin protection should not be neglected. While the laser beam is the primary hazard, secondary radiation and accidental exposure to reflected laser light can cause skin burns. Wearing protective clothing, such as lab coats or aprons made from flame-retardant materials, can provide an additional layer of safety.

In conclusion, while CNC laser cutters are powerful tools that offer precision and efficiency, they also pose significant safety risks. Equipping oneself with the right safety gear is not just a matter of compliance; it is an investment in one’s well-being and the longevity of the equipment. Protective eyewear, respiratory masks, hearing protection, fire safety accessories, proper ventilation, and skin protection are all key accessories that every CNC laser cutter owner should have to ensure a safe and productive working environment. By prioritizing safety, operators can focus on the creative possibilities of their laser cutting projects with peace of mind.

Must-Have Software for Enhancing CNC Laser Cutting Precision

Title: Key Accessories Every CNC Laser Cutter Owner Should Have

In the realm of manufacturing and design, CNC laser cutters have revolutionized the way we approach precision cutting and engraving. These powerful machines offer unparalleled accuracy and efficiency, but their performance is not solely dependent on their hardware. To truly harness the capabilities of a CNC laser cutter, one must consider the software ecosystem that complements it. This section delves into the must-have software that is essential for enhancing the precision and functionality of CNC laser cutting operations.

First and foremost, Computer-Aided Design (CAD) software is the cornerstone of any CNC laser cutting project. CAD programs allow users to create detailed and intricate designs that can be translated into precise cutting instructions for the machine. These tools offer a wide array of features, from 2D vector-based drafting to 3D modeling, which are crucial for visualizing the end product before any material is cut. By using CAD software, operators can make adjustments to designs with a high degree of accuracy, ensuring that the final cut is exactly as intended.

Transitioning from design to execution, Computer-Aided Manufacturing (CAM) software plays a pivotal role. CAM software takes the designs created in CAD and generates the machine code that controls the laser cutter, dictating its movements and operations. This software often includes material libraries and cutting presets, which help in optimizing the cutting parameters for different materials, such as adjusting the laser power, speed, and focus. By fine-tuning these settings, the software ensures that cuts are clean, precise, and consistent across different materials and thicknesses.

Another indispensable tool in the software suite is simulation software. Before the actual cutting begins, simulation software can predict how the laser cutter will behave, allowing operators to foresee potential issues such as collisions or inefficiencies in the cutting path. This preemptive analysis saves valuable time and resources by reducing the likelihood of errors during the actual cutting process. It also provides an opportunity for operators to refine their designs and cutting strategies, further enhancing the precision of the final product.

Furthermore, nesting software is a key accessory for those looking to maximize material utilization and minimize waste. Nesting software intelligently arranges the parts to be cut on the material sheet, optimizing the layout to fit as many parts as possible. This not only reduces material costs but also minimizes the time spent on repositioning and handling materials between cuts.

Lastly, machine control software is the interface through which operators interact with the CNC laser cutter. This software provides real-time feedback on the machine’s status and allows for adjustments to be made on-the-fly. It is essential for monitoring the cutting process, ensuring that the machine is operating within its parameters, and making quick corrections if necessary.

In conclusion, while a CNC laser cutter is a formidable tool in its own right, its true potential is unlocked through a suite of complementary software. From CAD programs that bring ideas to life to CAM and simulation software that translate those ideas into precise cuts, each piece of software is integral to the process. Nesting software ensures material efficiency, and machine control software provides the necessary oversight for smooth operation. Together, these software tools form the backbone of a high-precision CNC laser cutting system, enabling owners to achieve the best results with their equipment.

Conclusión

Conclusión:

Every CNC laser cutter owner should have a set of key accessories to ensure efficient, safe, and high-quality operations. These accessories include proper safety gear such as laser safety glasses and fire extinguishers, air assist systems for cleaner cuts, a reliable fume extraction system to maintain air quality, a cooling system to prevent overheating, a high-quality lens and mirror kit for optimal focus and reflection, a material support system like honeycomb beds for stability, and calibration tools for precision. Additionally, having a collection of spare parts and a maintenance kit on hand will minimize downtime. These accessories are essential for maximizing the performance and longevity of a CNC laser cutter.

Deja una respuesta