22Jan

What are cnc models for wood works?

Jorge Gonzales2022-03-18T14:30:03-07:00Do you know what the cnc designs for wood work are?

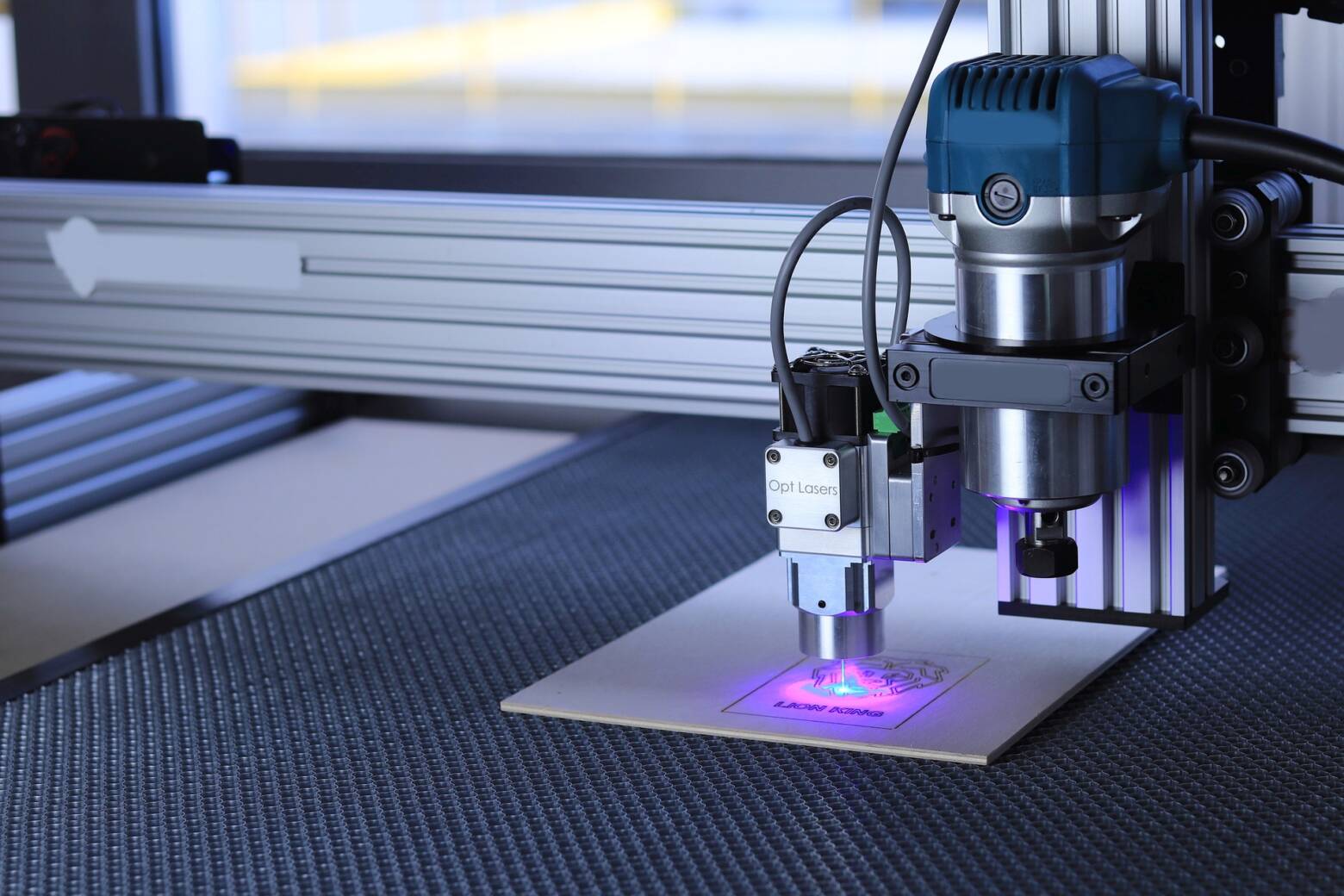

A guy working in my shop showed me a sample of wood he was printing in cnc. You can see in the picture that the print is already applied to the board. By “applied”, I mean that it is half cut and in fact you can pull it back and the portion you have printed already will easily move over to the other side, but is still pinned to the board so that it holds its position. You can see how thin it is.

I tried to imagine how I might use this. It does not seem like it would be very durable. But, if you are having this done for a lot of boards, each day you have to go over the same piece of work, it might be more cost effective. I may get around to having this done for my shop project. It would definitely make a great display!

Can I make a print like this?

Obviously, this is not going to hold the print on the back, unless you put some kind of pressure on it (like a band-aid) and then it will grip onto the board.

A simple cnc machine does not let you make this level of control. A spindle cannot perform this type of cutting. I am not even sure that a simple CNC could do this. But, a dedicated, CNC machine could be built that would allow you to print this type of material. It could even do a little vector drawing and printing, maybe you could do a small drawing like this…

To see what kind of shape this would make, take a look at my file box! I know I use these type of print for mine, and to build a little wooden box with it…

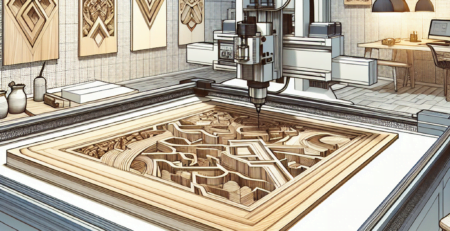

A CNC machine might be useful if you were working on something that is always in the same state. Like, if you have a bunch of boards that you need to cut out with various sizes in them.

Can I make this on a CNC machine?

In many ways I could build a simple CNC system and then have a couple of dedicated graphics design types modify it. But, I think I would much rather buy one and have it professionally made. But, if you decide you want to build it yourself, I’ll show you the basic hardware setup and how to modify a stock CNC.

How big should the print be?

How big the print is depends on how much is going on the back of the card. This is what I mean by “materials that are made to go on a ‘wall’”. You can get a couple of boards and carve the shapes for the front and back at the same time. But, if you want something that will hold a lot of material, you’ll need to make it.

I made the back for my book cover print at the same time as I did the front. It is one solid piece of plastic. The front can be made from two separate pieces, but you don’t want to get an entire board to use as one board. So, a number of years ago I got a CNC Machine with a cutting spindle.

This kind of machine has more than one spindle on the machine that can make use of different cut surfaces. This means you can make a much bigger print on the front side than you can the back side.

And, if you are going to use this material for other things, like a large display board, the smaller one is probably more practical. A 4 foot by 6 foot print would not be feasible.

You could do something similar with a glue gun and wood, but you would need multiple glue guns…

How many cut surfaces can you make?

This depends on what you want to use this on. You could try to make one side or the other, but that will not be as versatile. For example, one side will look very different from the other, it will bend, flex and more than likely, crack or stretch with use.

For a certain type of printed material (like this) I would probably want to make them all at the same time. So, make one side of it first, and then repeat. Make a few test prints and see what your best printing direction is. Make that a design standard.

This has been a great project to do! I would say “Thank You, thank you, thank you!!” for making this video. It was fun to do!

I have recently been thinking about some other “modular” CNC machines that could be made to make a workbench, some model trains and other things.

Thanks for reading!

Afterword

I wanted to thank you for your patience while I put this together!

If you have any questions about this, the CNC machine or the material, just ask in the comments

Author

Dedicated seller of intangible goods for business and people who like 3d cnc models for carvingl, 3d stl files for 3d printing, embroidery designs and 2d vectors for plotters or graphic designsing works.

Leave a Reply